OPTIMISATION

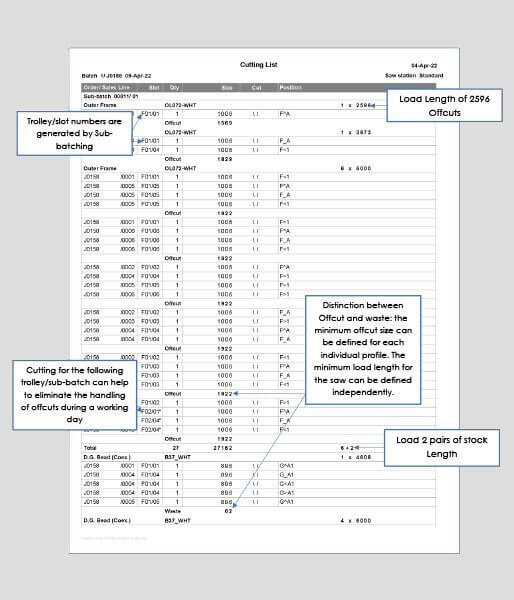

Once Sales Orders have been batched/scheduled for production, Windowmaker has a range of features to maximise your efficiency:

- Create optimum production sequences

- Use Sub-batching to improve production output

- Use Pairing and Material Optimisation with Reusable Offcuts to minimise waste

- Calculate machining requirements

WORK INSTRUCTIONS

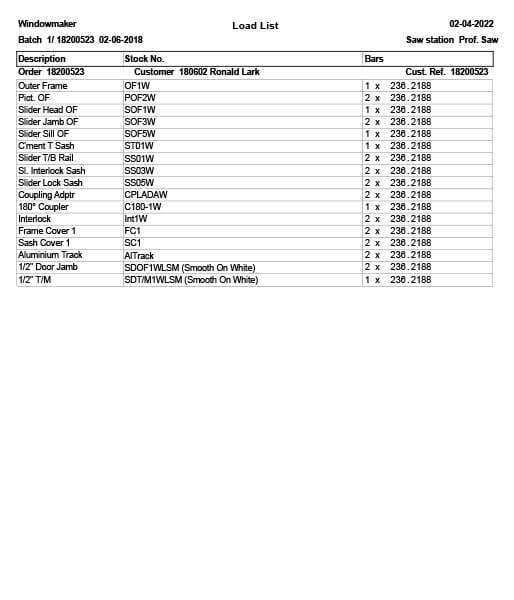

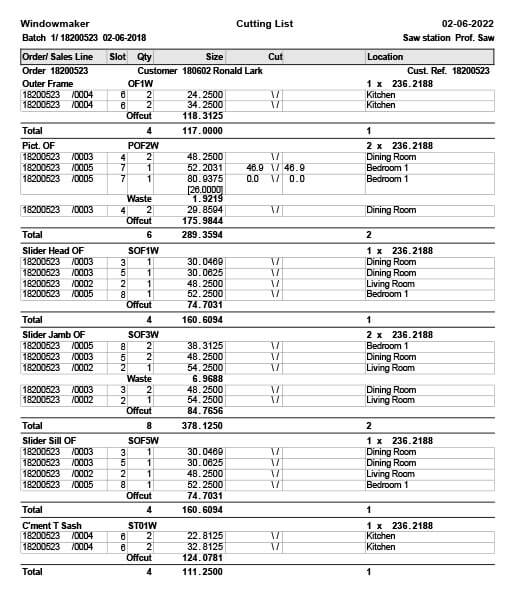

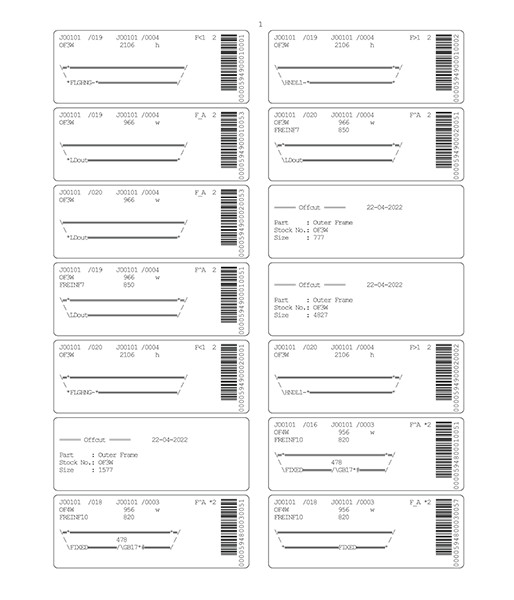

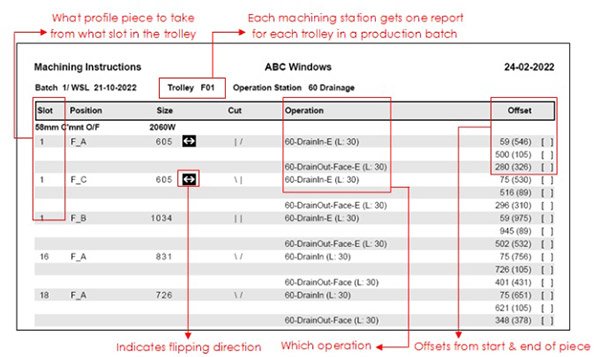

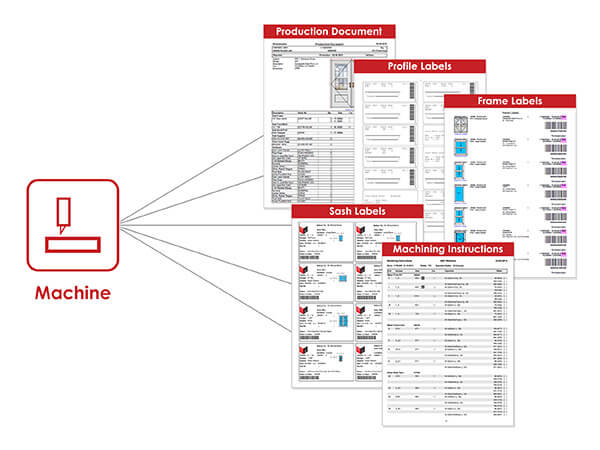

With the orders passed through into Production, Windowmaker can provide a variety of Works Instructions, including:

- Machine Links, to a variety of saws, working centres, welders and glass cutting tables

- Reports and Profile Labels, which can be fully customised to your requirements including text and graphics

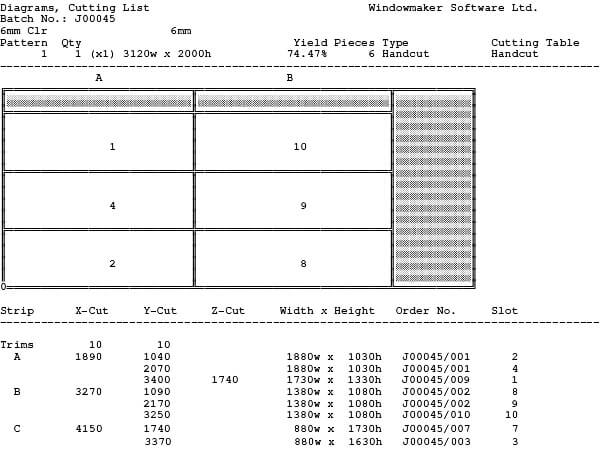

GLAZING

Windowmaker offers a variety of glass work instructions to monitor the processes right from cutting to installation. With a range of reports, ensure that you make the whole process hassle-free and quick!:

- A facility to optimise glass yield by automatically organising the cutting sequence of pieces

- Link to a variety of glass cutting tables

- Fully customizable Glass Labels & Reports

">

TRACK

Use barcode technology to keep a track of products progressed as on the manufacturing floor. Allocate tracking clients:

- to capture the data regarding the progress of frames, sashes and glass through the factory with statistics on standard and actual performance

- to procure clear and comprehensive work instructions including prioritized lists for station operator and

- to generate reports including comprehensive management information with labour performance & problem statistics